Views: 0 Author: Site Editor Publish Time: 2025-09-23 Origin: Site

Food processing equipment helps you handle food more efficiently, making each step less labor-intensive. You will find several main types, such as cleaning machines, slicers, mixers, grinders, ovens, freezers, and packaging systems. These machines, like vegetable washers or blast freezers from our product catalog, let you work faster and safer. You need to know about food processing equipment because it improves efficiency, ensures consistent quality, and supports food safety in the food processing industry. Newer machines, such as automated lines and advanced mixers, also help you create innovative products.

You will find many types of food processing equipment in the food industry. Each type helps you improve efficiency, safety, and product quality. The table below shows how industry standards classify the main categories and examples of processing equipment:

Category | Examples |

|---|---|

Cleaning and Washing Equipment | Vegetable Washers, Fruit Washers, Ultrasonic Cleaners |

Cutting and Chopping Equipment | Dicing Machines, Slicers, Choppers |

Mixing and Blending Equipment | Dough Mixers, Ribbon Blenders, Emulsifiers |

Cooking and Heating Equipment | Steam Cookers, Fryers, Ovens |

Cooling and Freezing Equipment | Blast Chillers, IQF Freezers, Refrigerated Conveyor Belts |

Specialized Equipment for Dairy | Pasteurizers, Homogenizers |

Meat Grinders, Deboning Machines | |

Specialized Equipment for Snacks | Extruders, Seasoning Applicators |

Specialized Equipment for Beverages | Filtration Units, Carbonation Systems |

Conveying Systems | Modular Belt Conveyors, Inclined Conveyors |

Packaging Machines | Vacuum Sealers, Carton Filling Machines, Thermoformers |

You need cleaning and washing equipment to remove dirt, pesticides, and pathogens from food. These machines help you meet strict safety standards and keep your products safe.

Vegetable washers, such as those in the Stabake product catalog, use water jets or ultrasonic waves to clean produce. You can process large batches quickly and reduce manual labor. In frozen food processing, washing and sanitizing equipment eliminates contaminants and pathogens, ensuring high sanitation standards. Automated wash systems in bakeries clean thousands of items every hour, saving resources and time.

Fruit washers work like vegetable washers but focus on delicate fruits. These machines gently remove surface residues without damaging the fruit. Commercial fruit washers from the catalog help you maintain quality and freshness. In general food processing, sanitation solutions replace manual cleaning, making your workflow more efficient.

Tip: All food-contact surfaces must be cleaned and sanitized frequently to prevent contamination. Cleaning compounds should be safe and effective, with proper documentation.

Cutting and chopping equipment lets you portion food accurately and consistently. You can choose from slicers, dicers, and industrial cutters based on your needs.

Slicers, such as those listed in the product catalog, help you cut vegetables, meats, and cheeses into uniform pieces. Industrial slicers process hundreds of kilograms per hour, making them ideal for busy kitchens and factories. Automation in these machines reduces human error and improves product quality.

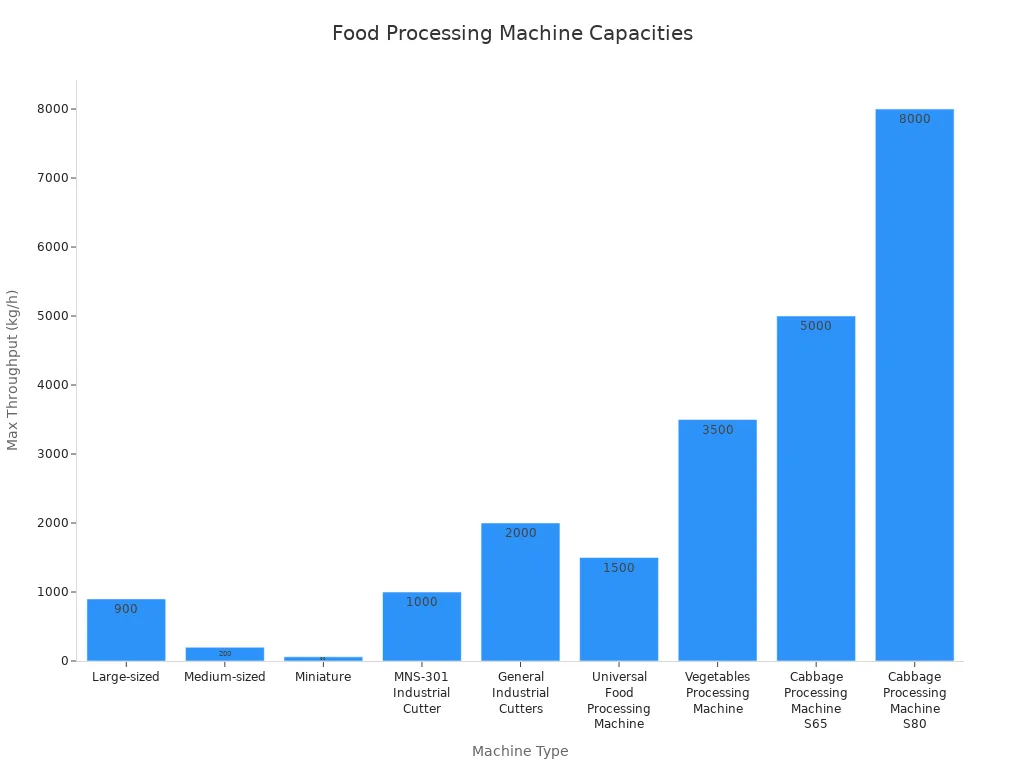

Dicers cut food into cubes or strips. You can use dicers for vegetables, fruits, and meats. Machines like the MNS-301 Industrial Fresh Vegetable Chopping Machine process up to 1000 kg/h, ensuring efficiency in large-scale production. Precision cutting guarantees uniformity, which is vital for cooking consistency and appearance.

Industrial food cutting machines ensure consistent portioning and sizing, which is crucial for maintaining uniform quality in processed food items.

Mixing and blending equipment combines ingredients to create doughs, sauces, and batters. You can select from different types of equipment depending on your application.

Dough mixers, such as spiral and planetary mixers from the catalog, are essential in bakeries. These machines knead dough efficiently, supporting various batch sizes. You can achieve consistent texture and hydration in bread and pastry production.

Sauce blenders mix liquids and solids to create smooth sauces and dressings. You can use continuous mixers for uninterrupted production or acoustic mixers for temperature-sensitive processes. These machines help you maintain product consistency and quality.

Drum mixers, fluidization mixers, and convective mixers also play important roles in food processing, blending powders and granular solids for nutrition and agriculture.

Mechanical processing equipment changes the physical form and size of food. You use these machines to grind, shape, and prepare ingredients for further steps in industrial food processing. These tools help you meet production goals and maintain product quality.

Mechanical processing equipment transforms raw materials into usable forms, making industrial food processing more efficient and consistent.

Grinding equipment reduces particle size and alters the structure of food. You rely on grinders and mills to prepare ingredients for baking, drinks, and supplements. Grinding is a key step in industrial food processing, especially when you need powders or fine textures.

Meat grinders, such as the MNS-301 Industrial Meat Grinder from the product catalog, help you process large batches of meat quickly. You use these machines to create ground beef, sausage fillings, and burger patties. Meat grinders decrease particle size and improve the texture of meat products. You can also use them to prepare ingredients for baby food and oil extraction.

Spice mills grind brittle foods like peppers, salt, and sugar. You use spice mills to produce powders for baking and seasoning. These machines play a vital role in industrial food processing, especially when you need consistent particle size for flavor and texture. Spice mills also help you prepare ingredients for supplements and drinks.

Processing Technique | Effects on Physical Properties of Food Products |

|---|---|

Milling | Alters morphology and functional properties of starch, increases solubility and swelling power, reduces phenols and dietary fiber content. |

Grinding | Decreases crystal structure and particle size, improves mechanical properties of starch-based films, enhances swelling power and thermal stability. |

Extrusion | Causes structural changes in starch, including gelatinization and degradation, affecting digestibility and nutritional characteristics. |

You must follow safety and hygiene guidelines when using grinding equipment in industrial food processing.

Proper equipment design and maintenance keep your workspace safe.

Check wheel balance to prevent vibrations and breakage.

Apply gradual and even pressure during operation.

Adjust the work rest close to the wheel.

Never exceed manufacturer speed specifications.

Take regular breaks to reduce hand-arm vibration syndrome.

Hygienic design prevents contamination from microbes and foreign bodies.

Forming machines shape food into uniform products. You use these machines to automate tasks and improve consistency in industrial food processing.

Dumpling makers, such as the Stabake Automatic Dumpling Machine, form dough and filling into precise shapes. You can produce hundreds of dumplings per hour, saving time and labor. These machines ensure each dumpling looks and tastes the same, which is important for quality control.

Noodle machines cut and shape dough into noodles of various sizes. You use noodle machines in industrial food processing to produce large quantities of noodles quickly. These machines help you maintain uniform thickness and length, which improves cooking results.

Forming machines offer several benefits in industrial food processing:

Increased efficiency: Automation cuts down manual labor and boosts production volume.

Consistency and precision: Machines minimize human error, ensuring uniform products.

Cost-effective: Automation reduces labor costs and material waste.

You also find other forming machines in industrial food processing, such as confectionary molders, bread molders, enrobing machines, and pie formers. These machines help you produce a wide range of products with consistent quality.

Industrial food processing equipment, including grinders and forming machines, supports food safety, quality, and sustainability. As demand for processed foods grows, advanced processing equipment becomes essential for meeting industry standards.

Heat processing equipment plays a vital role in the food production process. You use this type of processing equipment to cook, preserve, and ensure the safety of food. Heat treatment eliminates harmful microorganisms, extends shelf life, and helps maintain the quality of your products. When you select the right equipment, you protect consumers and improve efficiency in your operation.

Heat sterilization removes dangerous bacteria like Escherichia coli, Listeria, and Salmonella.

High temperatures reduce pathogens and inactivate spoilage enzymes.

Heat processing denatures proteins and disrupts cell structures, which preserves food and extends shelf life.

Cooking is one of the most common uses for heat processing equipment. You can choose from ovens and steamers, depending on your product and desired results.

Ovens, such as those in the Stabake product catalog, provide dry heat for baking bread, roasting meats, or preparing snacks. You can set precise temperatures and times to achieve consistent results. Ovens help you control browning and texture, which is important for baked goods and ready meals.

Steamers use moist heat to cook vegetables, seafood, and dumplings. This method helps retain nutrients and color. In your processing line, steamers from the catalog allow you to cook large batches quickly and evenly. Steam systems can reach up to 338°F (170°C) and often use low-cost fossil fuels for energy.

Tip: Sautéing and stir-frying preserve water-soluble vitamins, while boiling can destroy up to 70% of vitamin C in spinach. Use less water and shorter cooking times to keep nutrients.

Type of Equipment | Temperature Range | Energy Requirements |

|---|---|---|

Fossil Fuel Systems | Varies | Natural gas, oil, or coal |

Steam Systems | Up to 338°F (170°C) | Low-cost fossil fuels |

Electric Systems | Varies | Electricity |

Hydronic Systems | Varies | Hot water from a central boiler |

Hybrid Systems | Varies | Combination of fuel and electricity |

Pasteurization is a key step in the food production process. You use this processing equipment to destroy bacteria and extend shelf life without changing the taste or texture of food.

Pasteurizers, such as those available in the product catalog, heat liquids like milk, juice, and sauces to specific temperatures for set times. The three main techniques are:

Pasteurization Technique | Temperature (°C) | Time (minutes/seconds) | Effectiveness |

|---|---|---|---|

Low Temperature Long Time (LTLT) | 63 | 30 minutes | Excellent bacterial control |

High Temperature Short Time (HTST) | 72 | 15 seconds | Efficient and effective for large-scale operations |

Ultra High Temperature (UHT) | 135-150 | 1-3 seconds | Creates shelf-stable products without refrigeration |

You can use pasteurizers for milk, juices, soft drinks, beer, wine, cream, processed cheese, liquid eggs, syrups, sauces, soups, and ready meals.

Retort sterilizers use high pressure and temperature to process canned foods, soups, and sauces. These machines ensure that your products remain safe and shelf-stable for months. Retort systems from the catalog help you meet strict safety standards in large-scale operations.

Frying adds flavor and texture to many foods. You can choose from deep fryers and continuous fryers, depending on your production needs.

Deep fryers, such as those in the Stabake catalog, cook foods in hot oil. You use them for snacks, chicken, and potato products. Batch fryers require more operator attention and have oil turnover rates of 5 to 12 hours.

Continuous fryers use conveyor belts to fry foods nonstop. These machines are more energy efficient and have oil turnover rates of 5 to 10 hours. You can maintain oil quality and product shelf life by choosing the right fryer design and oil type.

Type of Fryer | Description | Oil Consumption Rate |

|---|---|---|

Batch Fryers | Used for frying foods in batches, requiring more operator attention. | 5 to 12 hours |

Continuous Fryers | Uses a conveyor belt for continuous frying, more energy efficient. | 5 to 10 hours |

Vacuum Fryers | Operates under vacuum and low temperature, preferred for minimal browning. | Higher cost, lower capacity |

Note: Low oil turnover rates help you maintain oil quality and extend the shelf life of fried products.

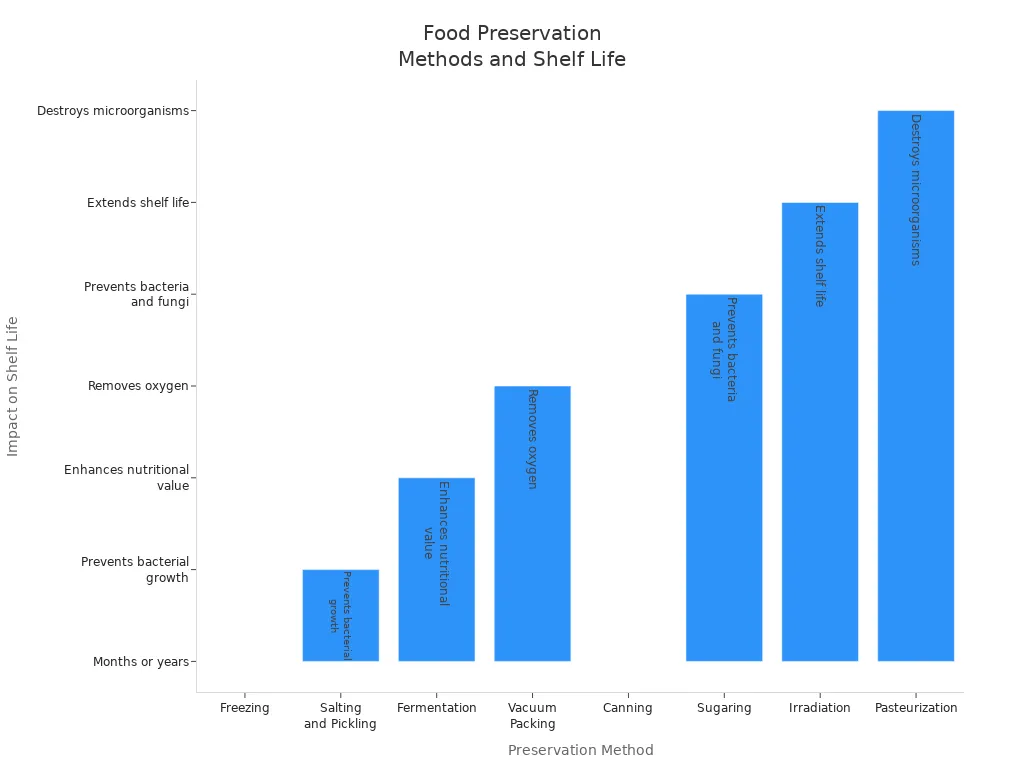

Preservation equipment helps you keep food safe and fresh for longer periods. You can use different methods to slow down spoilage, maintain quality, and reduce waste. The right equipment lets you extend shelf life and meet food safety standards. Here is a quick look at common preservation methods and their impact:

Preservation Method | Impact on Shelf Life | Benefits |

|---|---|---|

Freezing | Extends shelf life for months or years | Slows down spoilage, retains nutrients, preserves flavor and texture |

Salting and Pickling | Extends shelf life by preventing bacterial growth | Retains nutrients, enhances flavor, provides probiotic benefits |

Fermentation | Extends shelf life and enhances nutritional value | Increases vitamin bioavailability, promotes gut health |

Vacuum Packing | Extends shelf life by removing oxygen | Prevents bacterial growth, maintains quality without preservatives |

Canning | Extends shelf life for months or years | Kills harmful microorganisms, maintains flavor and nutrients |

Sugaring | Prevents growth of bacteria and fungi | Maintains texture and enhances flavor |

Irradiation | Enhances food safety and extends shelf life | Eliminates insects and microbes |

Pasteurization | Extends shelf life by destroying harmful microorganisms | Ensures food safety, commonly used for liquids like milk and juices |

Refrigeration equipment keeps food at low temperatures to slow down the growth of bacteria and mold. You use these machines to store perishable items and maintain freshness.

Blast freezers, like those in the Stabake catalog, rapidly lower the temperature of food. You can freeze large batches of meat, seafood, or baked goods in a short time. This process locks in nutrients and texture. Blast freezers help you prevent ice crystal formation, which protects food quality.

Cold storage units provide stable, low temperatures for long-term storage. You rely on these systems to keep fruits, vegetables, and dairy products fresh. Cold storage facilities use a lot of electricity. Energy is the second highest operating cost for these facilities. You can save up to 30% on electricity by improving insulation and using tighter seals. ENERGY STAR-qualified refrigerators can save you money over time, especially if you choose efficient models.

Operators often look for new technologies to balance energy costs with temperature stability. Continuous refrigeration is necessary for frozen foods, which increases energy use.

Drying removes moisture from food, making it less likely to spoil. You can use different types of dryers depending on the product.

Food dryers, such as tray dryers and rotary dryers, use heated air to remove water from food. You can dry herbs, spices, and grains in batches or continuously. Tray dryers work well for small items like herbs, while rotary dryers handle larger, granular materials.

Dehydrators, including fluidized bed dryers and vacuum dryers, help you process fruits, vegetables, and powders. Fluidized bed dryers suspend food in hot air for even drying. Vacuum dryers operate at lower temperatures, which protects heat-sensitive foods. Spray dryers turn liquids into powders, perfect for milk or instant coffee.

Drying Equipment | Description | Suitable Materials |

|---|---|---|

Tray dryers | Batch dryers using heated air to dry materials spread on trays. | Herbs, spices, pharmaceuticals |

Rotary dryers | Continuous dryers that tumble materials in a rotating drum with hot air. | Granular materials like minerals, fertilizers |

Fluidized bed dryers | Suspend materials in an upward flow of hot air for uniform drying. | Fine particles, powders, granules |

Spray dryers | Atomize liquids into fine droplets and dry them in hot air, producing powdered products. | Milk powder, instant coffee, detergents |

Vacuum dryers | Operate at reduced pressure for lower temperatures, minimizing degradation of heat-sensitive materials. | Pharmaceuticals, chemicals, food ingredients |

You can choose from convective drying, spray drying, freeze-drying, or osmotic dehydration, depending on your needs.

Vacuum sealing equipment removes air from packaging to protect food from spoilage. You can use this method to keep food fresh and reduce waste.

Vacuum sealers, like those in the product catalog, extend the shelf life of food by three to five times compared to regular storage. You can store meat, cheese, and produce for longer periods. Vacuum sealing stops bacteria and mold from growing. It also keeps the taste, texture, and nutrients intact. Reusable vacuum bags help you cut down on single-use plastics.

Vacuum sealing creates an anaerobic environment, which limits the growth of bacteria and fungi.

You can organize your storage better and reduce food waste.

Modified Atmosphere Packaging (MAP) machines replace the air inside a package with a special gas mix. You use MAP machines to keep products like salads, baked goods, and snacks fresh. This method slows down spoilage and keeps food safe without using preservatives.

Vacuum sealing and MAP machines both help you preserve food quality and safety. These tools make your operation more efficient and sustainable.

Packaging equipment protects food during storage and transport. You rely on these machines to keep products safe from contamination and damage. Proper packaging helps you meet food safety standards and deliver fresh products to customers. You also improve efficiency and reduce waste in your operation.

Packaging plays a key role in food safety and regulatory compliance. Machines must meet standards like the Food Safety Modernization Act (FSMA), European Machinery Directive, and Electrical Safety Standards. These rules help you prevent foodborne illnesses and ensure safe operation.

Compliance Standard | Importance |

|---|---|

Food Safety Modernization Act (FSMA) | Prevents foodborne illnesses by ensuring safe packaging processes. |

European Machinery Directive | Ensures packaging machines meet health and safety requirements. |

Electrical Safety Standards | Prevents electrical hazards through proper wiring and component safety. |

Filling machines help you portion liquids, powders, and granules into containers. You use these machines to maintain product quality and control costs. Accuracy matters for regulatory compliance and market competitiveness.

Equipment Type | Accuracy Rate |

|---|---|

Powder Filling Machine | High precision |

Liquid Filling Machine | Moderate precision |

Granular Filling Machine | Variable precision |

Filling machines are essential in food, pharmaceuticals, and chemicals.

You need accurate filling to meet quality standards.

Filling accuracy affects product quality, cost control, and competitiveness.

Liquid fillers, such as those in the Stabake product catalog, dispense sauces, juices, and dairy products into bottles or pouches. You can adjust settings for different viscosities and container sizes. These machines help you avoid spills and maintain hygiene.

Powder fillers measure and dispense dry ingredients like flour, spices, or supplements. You use these machines for products that require precise dosing. Powder filling machines from the catalog offer high precision, which helps you meet strict quality standards.

Machine Type | Description | Throughput Rate (bpm) |

|---|---|---|

Form Fill Seal (VFFS/HFFS) | Forms bags, fills them, and seals them. | N/A |

Multilane Stick Pack Machines | Packages small packets of powder or liquid products. | N/A |

Premade Pouch Fill and Seal | Fills premade pouches and seals them. | N/A |

Sealing and wrapping equipment keeps food fresh and prevents leaks. You use these machines to create airtight packages and tamper-evident seals.

Sealing Machine Type | Suitable Industries | Application Range | Key Features | Material Compatibility |

|---|---|---|---|---|

Heat Sealing Machines | Various industries | Wide range of products | Versatile, strong seals | Plastics, foils, laminates |

Shrink Wrappers (L-Bar) | E-commerce, Retail | Individual items, small packages | Quick operation | Plastic films, shrink wraps |

Heat sealers, such as those in the Stabake catalog, use heat to bond plastic, foil, or laminate packaging. You can seal bags, pouches, and trays quickly. These machines create strong, leak-proof seals that protect food from moisture and air.

Shrink wrappers wrap products in plastic film and use heat to shrink the film tightly. You use shrink wrappers for snacks, baked goods, and retail items. L-Bar sealers from the catalog offer fast operation and professional results.

Labeling equipment helps you apply product information, barcodes, and expiration dates. You need clear labels for traceability and compliance.

Label applicators place labels on bottles, jars, and boxes. You can choose machines that handle different shapes and sizes. These machines help you speed up production and reduce errors.

Inkjet coders print batch numbers, dates, and codes directly onto packaging. You use these machines to meet traceability requirements and provide information to customers. Inkjet coders from the catalog offer flexible printing options for various packaging materials.

Tip: You improve food safety, efficiency, and compliance by choosing the right packaging equipment. Modern food processing equipment lets you meet industry standards and deliver high-quality products.

Specialized types of food processing equipment help you handle unique tasks or large-scale production. These machines often combine several steps into one system or focus on specific foods. You can boost efficiency and product quality by choosing the right specialized equipment for your operation.

Automated lines let you process food with minimal manual work. You can link machines for washing, cutting, cooking, and packaging into one continuous system. This setup helps you save time and reduce errors.

Multi-function lines combine several processing steps. For example, the Stabake Multi-Function Vegetable Processing Line washes, peels, slices, and packages vegetables in one flow. You can adjust settings for different products. These lines help you increase output and maintain consistent quality. Many factories use automated lines to meet high demand and strict safety standards.

Automated lines reduce labor costs and improve food safety. You can track each step and make quick adjustments if needed.

Some machines work best for certain foods. You can find equipment designed for bakeries, snack factories, or other food sectors. These machines help you create products with the right texture, shape, and taste.

Bakery machines handle dough mixing, proofing, shaping, and baking. You can use spiral mixers, dough dividers, and automatic bread lines from the product catalog. For example, the Stabake Automatic Bread Production Line mixes, shapes, and bakes bread with little human input. You get uniform loaves and pastries every time. These machines help you keep up with large orders and maintain high standards.

Spiral mixers knead dough quickly and evenly.

Dough dividers portion dough for rolls or buns.

Automatic proofers control temperature and humidity for perfect rising.

Snack food machines help you make chips, crackers, and other treats. You can use extruders, seasoning applicators, and continuous fryers from the catalog. The Stabake Snack Food Extruder shapes dough into curls, rings, or sticks. You can add flavors with a seasoning tumbler. Continuous fryers cook snacks evenly and quickly.

Snack Machine Type | Main Function | Example from Catalog |

|---|---|---|

Extruder | Shapes dough into snacks | Stabake Snack Food Extruder |

Seasoning Applicator | Adds flavor coatings | Stabake Seasoning Tumbler |

Continuous Fryer | Fries snacks in large batches | Stabake Continuous Fryer |

You can choose industry-specific machines to match your product goals. These tools help you stay competitive and meet customer expectations.

Food processing equipment shapes the future of the food processing industry. You see rapid growth in this sector, as shown below:

Year | Market Size (USD Billion) | CAGR (%) |

|---|---|---|

2023 | 52.69 | 4.0 |

2030 | 112.45 | 5.5 |

You benefit from safer, more efficient, and higher-quality foods because each equipment type supports strict standards. The industry now focuses on:

Automation and smart technology

Convenience foods for busy lifestyles

Sustainable processing methods

You can explore solutions for every need by reviewing the latest machines in the product catalog. These innovations help you meet changing demands and improve your operation.

Food processing equipment includes machines that help you clean, cut, cook, mix, preserve, and package food. These tools make food safer and production faster. You can find many types in the Stabake product catalog.

Automated machines save you time and reduce mistakes. You can produce more food with less effort. Automation also helps you keep food safe and consistent.

First, decide what foods you want to make. Next, check your production size and budget. Look for machines that match your needs in the Stabake catalog. Ask for advice if you feel unsure.

You should check for safety guards, emergency stops, and easy-to-clean surfaces. Machines must meet food safety standards. Always follow the manufacturer’s instructions.

You should clean machines after every use. Regular cleaning prevents bacteria and keeps food safe. Some machines, like vegetable washers, have automatic cleaning cycles.

Some machines, like mixers or slicers, work with many foods. Others, such as dumpling makers, handle only one type. Always check the product details before you buy.

You can visit trusted suppliers like Stabake. They offer a wide range of machines for cleaning, cutting, mixing, and packaging.

Tip: Always read reviews and ask for product demonstrations before you decide.