Views: 0 Author: Site Editor Publish Time: 2025-09-23 Origin: Site

Advanced deep frying equipment helps you achieve faster cooking times and consistent results. Choosing the right deep frying equipment, such as a fryer or other essential tools, increases productivity in busy kitchens and improves food quality at home. Gas deep frying equipment holds a significant market share due to efficient heat transfer and reliable temperature control. Electric deep frying equipment offers energy savings and automatic settings. You can find deep frying equipment like pans and baskets that suit different needs and workflows. The table below compares factors that affect food quality in commercial and home settings:

Factor | Commercial Settings | Home Settings |

|---|---|---|

Temperature Control | Specialized deep frying equipment provides better control | Limited deep frying equipment leads to inconsistency |

Frying Fat Condition | Maintained through regular monitoring | Often neglected, affecting quality |

Equipment Design | Optimized deep frying equipment for consistent results | Basic deep frying equipment leads to variable outcomes |

Knowledge of Techniques | Professional training enhances quality | Lack of training results in poor outcomes |

Tip: Explore expert reviews and product comparisons before investing in new deep frying equipment.

You can dramatically increase your kitchen’s output with advanced deep frying equipment. Modern fryers use precise temperature controls to create optimal cooking conditions. Smart automation reduces human error and boosts efficiency. Large cooking baskets let you prepare high volumes of fried food quickly. Fast heat recovery keeps cooking temperatures steady, even when you add cold food. Powerful heating elements cut down cooking times, so your staff can manage multiple tasks at once. Commercial fryers often feature higher oil capacities, ranging from 10 to 90 pounds, which helps maintain temperature stability and supports continuous cooking. Quick heating elements bring oil to the right temperature rapidly, allowing you to serve more customers in less time. Proper oil management systems, such as those found in many products from Stabake Food Machine, further enhance cooking efficiency.

Tip: Choose a fryer with a large basket and high oil capacity if you want to maximize output during peak hours.

Consistency matters in every commercial kitchen. Advanced fryers include a 'cold zone' that lets food particles settle without burning, which keeps the oil fresh and improves the taste of each batch. Precise temperature control ensures the oil stays steady, so you get crispy, perfectly cooked food every time. Programmable settings allow you to set specific cooking times and temperatures for different menu items. This automation means every dish comes out the same, no matter who operates the fryer. Oil filtration technology extends the life of the oil and maintains food quality. Cleaner oil means every batch tastes fresh, which is vital for customer satisfaction.

Note: Consistent results build your reputation and keep customers coming back for your fried food.

Advanced deep frying equipment saves you time in the kitchen. Professional fryers eliminate the need to monitor food temperature constantly. They heat up quickly, so you can start cooking without waiting for oil or an oven to preheat. Larger baskets let you cook more food at once, reducing the number of batches needed. These fryers maintain consistent temperatures, which prevents food from absorbing too much oil and ensures even cooking. If you have a busy schedule, you will appreciate how quickly these fryers heat up and cook food, making meal prep much faster.

Heats up quickly and cooks food fast

Ideal for busy schedules, significantly reducing meal prep time

Larger baskets enable cooking more food at once

Safety features play a crucial role in both commercial and home kitchens. Modern fryers come equipped with automatic shut-off systems, cool-touch exteriors, and secure lids to prevent accidents. These safety features protect you from burns and oil splatters. Many deep frying equipment models also include overheat protection and non-slip feet for added stability. By choosing equipment with advanced safety features, you reduce the risk of kitchen injuries and create a safer cooking environment for everyone.

Safety features are essential for peace of mind, especially when cooking with hot oil.

Choosing the right deep frying equipment can transform your kitchen’s productivity and food quality. You need to consider several key features, compare different deep fryer types, and balance your budget with performance needs. Whether you run a busy restaurant or cook at home, understanding these factors helps you make the best choice.

Capacity determines how much food you can fry at once. In commercial kitchens, oil capacities between 50 and 75 pounds work best for high-volume operations. Large baskets let you cook more food in fewer batches, which saves time and energy. Home cooks may prefer smaller models, but even at home, a larger basket can help when you cook for family gatherings or parties.

Feature | Description |

|---|---|

Capacity | Oil capacities between 50-75 pounds are ideal for high-volume operations. |

Power | BTU ratings from 136,000 to 170,000 ensure quick recovery times for consistent cooking. |

Burner | Tube-type burners provide efficient heat transfer, maintaining temperature during cooking. |

Tip: For commercial use, select a fryer with a large oil tank and basket. For home use, choose a model that fits your typical meal size.

Temperature control is one of the most important features in any deep frying equipment. You need to maintain proper oil temperature to achieve crispy fries and tender chicken. Advanced fryers offer digital displays and programmable settings, which help you set and hold the exact temperature you need. Consistent temperature control prevents food from absorbing too much oil and ensures even cooking. High-quality materials, such as enameled cast iron, also help maintain steady heat.

Note: Look for fryers with precise temperature control to improve both productivity and food quality.

Oil filtration systems extend the life of your oil and keep food tasting fresh. In commercial kitchens, a well-designed cool zone prevents food particles from burning, which helps maintain oil quality. Many modern fryers include built-in filtration systems that make cleaning easier and reduce oil costs by up to 40%. Home fryers with simple filtration features also help you save money and improve taste.

Cleaner oil means better-tasting food.

Filtration systems reduce waste and lower operating costs.

You can choose between electric and gas fryers, each with unique advantages. Electric fryers offer high energy efficiency, with cooking energy efficiency rates around 87%. They recover temperature quickly and are easy to clean. Gas fryers, on the other hand, have lower annual energy costs and provide strong output, especially in high-volume settings. Gas tube-type fryers work well for foods with heavy sediment, while open pot fryers are easier to clean.

Fryer Type | Cooking Energy Efficiency | Annual Energy Cost | Lifetime Energy Cost | Lifetime Energy Cost Savings |

|---|---|---|---|---|

Electric | 87% | $1,360 | $11,874 | $3,854 |

Gas | 72% | $533 | $4,321 | $6,030 |

Tip: Electric fryers suit kitchens that need fast recovery and easy cleaning. Gas fryers work best for high-output, cost-conscious operations.

Besides large fryers, you may need specialized pans and baskets. A good pair of tongs and a spider skimmer help you handle food safely and efficiently. Spider skimmers remove food and debris from hot oil, which keeps your oil clean and your food crisp. In commercial kitchens, stand-alone fryers and countertop models offer flexibility and space-saving options. Specialty fryers, such as those for donuts or chicken, can improve results for specific menu items.

Type of Fryer | Advantages | Disadvantages |

|---|---|---|

Stand-Alone Fryers | Durable, easy to use, and simple maintenance. Available in various sizes. | N/A |

Gas Tube Type | Energy efficient, versatile for high sediment items, prolongs oil life. | Difficult to clean, 20% of oil rests in cold zone. |

Gas Open Pot | Easy to clean, allows more oil use in vat. | Less energy efficient, smaller cold zone. |

Gas Flat Bottom | Ideal for wet battered foods, allows foods to float. | High maintenance, sediment can burn oil. |

Electric Fryer | Energy efficient, fast temperature recovery, easy to clean. | Electric costs can be high, difficult to clean. |

Countertop Fryers | Space-saving, easy to move, less oil usage. | N/A |

For a wide range of commercial and home deep frying equipment, including specialty fryers and accessories, explore options from Stabake Food Machine.

You can find budget-friendly deep frying equipment for both home and commercial use. Smart buyers consider the total cost of ownership, including energy savings and oil life extension. ENERGY STAR certified fryers save hundreds of dollars each year on utility bills. Advanced filtration systems reduce oil costs by up to 40%. Many brands offer flexible financing and lease-to-own programs, making it easier to manage upfront costs.

Feature | Description |

|---|---|

Total Cost of Ownership | Smart buyers consider the total cost, including energy savings and oil life extension. |

Energy Efficiency | ENERGY STAR certified fryers save hundreds annually on utility bills. |

Oil Cost Reduction | Advanced filtration systems can reduce oil costs by 30-40%. |

Maintenance | Higher-quality fryers require less maintenance and have longer service lives. |

Labor Savings | Automated features reduce staff time spent managing fryers, allowing focus on revenue tasks. |

Financing Options | Flexible financing options available to help manage upfront costs. |

Lease-to-Own Programs | Simple qualification processes with terms from 12 to 60 months. |

Premium deep frying equipment offers better efficiency, durability, and advanced features. Higher-priced models, ranging from $1,200 to $15,000, deliver lower operational costs over time. ENERGY STAR models may cost more upfront but save money on utilities. Advanced features, such as programmable temperature control and built-in filtration, reduce oil and labor costs. High-quality fryers require less maintenance and last longer, which means fewer replacements and repairs.

Price Range | Performance Implications |

|---|---|

$1,200 - $15,000 | Higher-priced models offer better efficiency and durability, leading to lower operational costs over time. |

ENERGY STAR models | Initial higher cost can save hundreds annually on utility bills. |

Advanced features | Can reduce oil costs by 30-40% by extending oil life. |

Maintenance | Higher-quality fryers require less maintenance and have longer service lives. |

Note: Investing in premium deep frying equipment pays off in the long run through energy savings, reduced oil costs, and fewer repairs.

When you select deep frying equipment, always read expert reviews and compare product features. Look for models that match your kitchen’s needs, whether you want a high-capacity fryer for a restaurant or a compact model for home use. Accessories like a spider skimmer or a good pair of tongs improve safety and efficiency. For reliable options and expert recommendations, visit Stabake Food Machine.

Optimizing your kitchen workflow starts with a smart layout and efficient processes. Advanced deep frying equipment can help you create a kitchen that runs smoothly, even during the busiest hours.

Placing your fryer in the right spot makes a big difference in how your kitchen operates. A well-designed kitchen supports efficiency, safety, and compliance. When you position your fryer close to prep and holding stations, you reduce unnecessary movement and speed up service. This setup helps your team access ingredients and equipment quickly, which is especially important during peak times. In fact, a well-planned kitchen can boost productivity by up to 30%. Compact fryers with adjustable capacity, like those available from Stabake Food Machine, help you make the most of your space and keep your workflow smooth.

Tip: Place your fryer near breading and holding areas to streamline the cooking process and minimize cross-traffic.

Integrating your fryer into the existing workflow requires careful planning. Advanced fryers with quick heating elements and programmable controls can transform your kitchen’s productivity. Features like multiple cooking baskets and easy cleanup options help you handle high demand without slowing down. You should also consider safety features, such as fire suppression systems and proper ventilation, to protect your staff and equipment. Positioning your frying station as part of an assembly line reduces bottlenecks and keeps your team focused on their tasks.

Arrange equipment to support a logical flow.

Keep emergency exits clear and maintain regular cleaning routines.

Preparation is key to a successful frying operation. Start by organizing your ingredients and tools before you begin. Make sure your fryer is clean and filled with fresh oil. Set the oil temperature between 350-375°F for the best results. Built-in filtration systems help you maintain oil quality and flavor, which leads to better-tasting food. Using a fryer with precise temperature controls, like those from Stabake Food Machine, ensures your food cooks evenly every time.

Note: Consistent prep steps lead to faster service and higher food quality.

Good staff coordination keeps your kitchen running smoothly. Assign clear roles to each team member, such as prepping, frying, and plating. Train your staff to use the fryer safely and efficiently. Regular safety and maintenance protocols, including cleaning the fryer and checking emergency exits, help prevent accidents and downtime. When everyone knows their responsibilities, your kitchen can handle busy periods with ease.

Hold brief meetings before each shift to review tasks.

Encourage communication to solve problems quickly.

By focusing on layout, integration, and teamwork, you can maximize the benefits of your advanced fryer and create a productive kitchen environment.

Modern deep frying equipment uses advanced technology to help you cook faster, safer, and with better results. Automation features in today’s fryers make your kitchen more efficient and help you maintain high standards every day.

Smart controls in a fryer let you set precise cooking times and temperatures for each menu item. You can program cycles for different foods, so you do not need to watch the fryer constantly. This feature helps you avoid overcooking or undercooking. Many commercial fryers, like those from Stabake Food Machine, offer digital interfaces that make programming easy. You save time and reduce mistakes, which boosts productivity.

Diagnostics tools in modern fryers help you spot problems before they cause downtime. These systems monitor the fryer’s performance and alert you if something needs attention. For example, if the oil temperature drops or a part needs cleaning, the fryer will notify you. This keeps your equipment running smoothly and reduces repair costs.

Here is a table showing recent advancements in smart controls and their benefits:

Advancement | Benefit |

|---|---|

Intelligent inventory management | Ensures efficient sourcing of ingredients, addressing supply chain issues |

Robotic cooking equipment | Fills labor shortages, enhancing operational efficiency |

Oil filtration systems | Automates oil management, improving safety and reducing maintenance tasks |

Energy-efficient technology | Contributes to sustainability and reduces overhead expenses |

Smart features in fryers | Enhances safety and automation in deep frying operations |

Tip: Use fryers with smart controls to simplify your workflow and improve food consistency.

Oil management is a key part of any frying operation. Filtration systems in a fryer remove food particles and contaminants from the frying oil. This process extends the life of the oil and keeps your food tasting fresh. Clean oil also helps you meet health standards and reduces the risk of foodborne illnesses. Regular filtration improves the taste and texture of fried foods. You spend less on oil because you do not need to replace it as often.

Advanced oil management systems lead to significant cost savings by reducing oil purchases.

These systems prolong the life of the oil, meaning less frequent replacements.

Filtration systems keep the oil clean, which helps maintain its quality for a longer period.

Regular oil filtration improves the taste and texture of fried foods.

Filtration systems in deep frying equipment enhance oil longevity by removing food particles and contaminants that can degrade the oil. This not only extends the oil's life but also improves the taste and safety of the fried foods. The quality of the oil is crucial, as it can constitute a significant portion of the final product, affecting flavor, healthiness, and shelf life. Effective filtration helps maintain the oil's quality by addressing issues like free fatty acids, which are key indicators of oil degradation.

Quality sensors in a fryer monitor the condition of the frying oil. These sensors check for signs of oil breakdown, such as changes in color or the presence of free fatty acids. When the oil needs changing, the fryer alerts you. This feature helps you avoid using degraded oil, which can harm food quality and safety. By using fryers with quality sensors, you protect your customers and your reputation.

Reducing the need to handle hot oil lowers the risk of accidents in the kitchen.

Clean oil helps kitchens comply with health regulations, reducing the risk of foodborne illnesses.

Note: Explore fryers with advanced oil management and smart controls at Stabake Food Machine to upgrade your kitchen’s technology.

Keeping your fryer in top condition helps you avoid costly breakdowns and ensures safe, high-quality food. Regular cleaning and preventive care not only extend the life of your fryer but also keep your kitchen running smoothly. Advanced models, like those from Stabake Food Machine, make maintenance easier with features designed for quick cleaning and simple operation.

You should clean your fryer every day to prevent grease and debris from building up. This routine keeps your equipment efficient and your food tasting fresh. Follow these steps for daily cleaning:

Remove food particles and debris from the oil.

Filter the oil to maintain quality and efficiency.

Wipe down chrome and stainless-steel surfaces using non-abrasive cleaners.

Clean fryer baskets to prevent contamination.

Always wear personal protective equipment when handling hot oil or cleaning chemicals.

Tip: Daily cleaning reduces the risk of clogs and keeps your fryer working at its best.

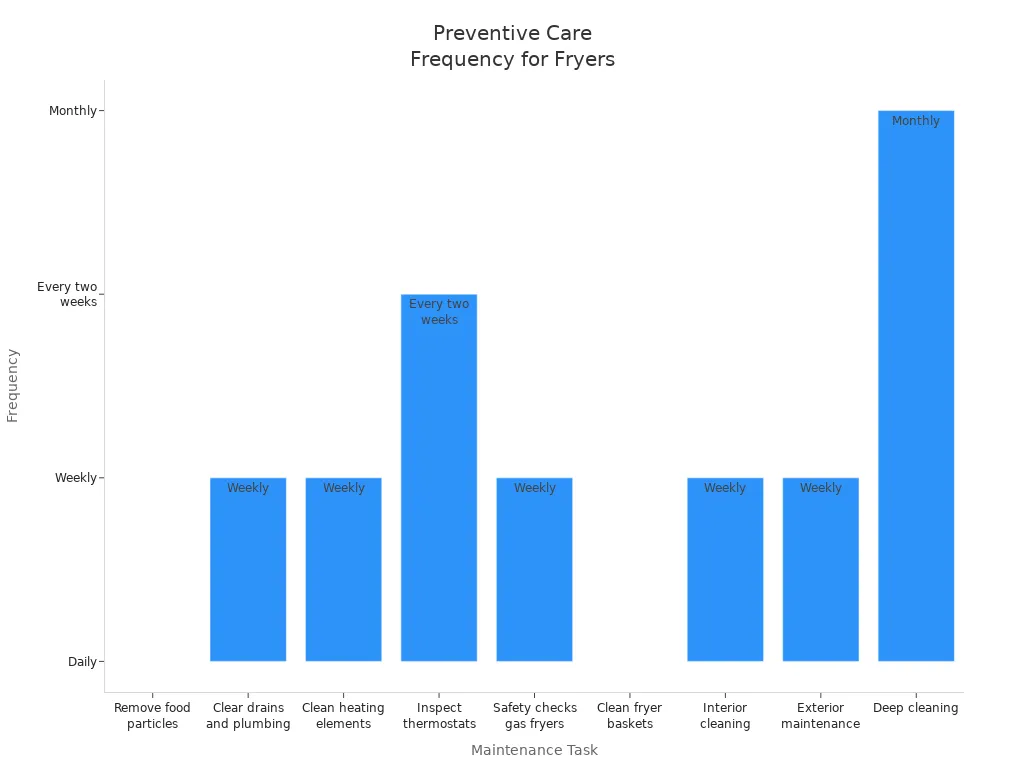

Weekly maintenance goes deeper to catch issues before they become problems. You should:

Clear drains and plumbing to avoid clogs.

Inspect and clean heating elements for steady temperature control.

Perform safety checks, especially if you use a gas fryer.

Clean the interior and exterior to maintain hygiene and prevent electrical hazards.

Schedule a deep cleaning session to remove grime from hard-to-reach areas.

Note: Use caution when cleaning the interior to avoid damaging electrical parts.

Keeping spare parts on hand helps you fix small issues quickly. Stock items like gaskets, filters, and heating elements. This practice reduces downtime and keeps your fryer ready for busy shifts.

Building a relationship with a reliable service partner ensures fast repairs and expert advice. Regular check-ups from professionals help you spot problems early and keep your fryer running efficiently. Many commercial kitchens choose service plans from trusted brands, such as those offered by Stabake Food Machine.

Maintenance Task | Frequency | Purpose |

|---|---|---|

Remove food particles and debris | Daily | Prevents clogs and ensures even cooking. |

Clear drains and plumbing | Weekly | Avoids clogs that can disrupt fryer operation. |

Inspect and clean heating elements | Weekly | Ensures consistent temperature for optimal cooking. |

Inspect thermostats | Every two weeks | Maintains precise temperature control. |

Safety checks for gas fryers | Weekly | Identifies potential hazards. |

Clean fryer baskets | Daily | Maintains cooking quality. |

Interior cleaning | Weekly | Reduces oil contamination. |

Exterior maintenance | Weekly | Ensures kitchen hygiene. |

Deep cleaning | Monthly | Prevents long-term maintenance issues. |

Regular cleaning and preventive care make your fryer easier to operate and maintain. Advanced fryers with simplified cleaning processes and precise controls help you save time and money. You also improve kitchen productivity and safety by choosing equipment designed for easy maintenance.

Proper training ensures you and your team use the fryer safely and efficiently. Hands-on training gives you real experience with the equipment, building confidence and skill. You learn best when you can practice with the fryer, not just read about it. Effective programs break down complex steps into simple actions. Both new hires and experienced staff benefit from a modular approach, which covers basics and advanced techniques.

Training should include:

Clear safety protocols for fryer operation

Daily startup and shutdown procedures

Proper oil filtering and handling

Location and use of emergency shutoff switches

Tip: Practice with the fryer regularly to keep your skills sharp and reduce the risk of accidents.

Every kitchen needs a clear emergency plan. You should know how to respond if a fryer malfunctions or if there is a fire. Make sure everyone can locate emergency shutoff switches and fire extinguishers. Hold regular drills so your team reacts quickly in real situations. Post emergency instructions near the fryer for easy reference.

Review emergency plans during staff meetings.

Update procedures when you add new equipment.

Managing oil waste helps you save money and protect the environment. When you optimize oil usage, you reduce how often you need to replace it. This lowers your operational costs and keeps your fryer running smoothly. Advanced filtration systems, like those found in many Stabake Food Machine models, help you extend oil life and improve food quality.

Evidence | Explanation |

|---|---|

Optimizing oil usage | Reduces the frequency of oil replacements, leading to lower operational costs. |

Minimizing operational costs | Effective oil management practices lead to longer oil life and better food quality, enhancing overall kitchen sustainability. |

Note: Cleaner oil means tastier food and less waste.

Reducing energy use in your kitchen starts with the right fryer and smart habits. Choose high-oleic oils, such as sunflower or canola, to extend oil life and reduce changes. Use filtration systems to keep oil fresh and avoid overheating by maintaining oil temperatures between 325°F and 375°F. Batch frying helps you keep temperatures stable and minimize oil absorption. Always dispose of used oil properly to prevent environmental harm.

Strategy | Description |

|---|---|

Choosing the Right Oil | Opt for high-oleic oils like sunflower or canola to extend oil life and reduce changes. |

Maximizing Oil Life | Use filtration systems to maintain oil quality and prevent degradation. |

Temperature Management | Keep frying oil within 325°F to 375°F to avoid overheating and breakdown. |

Reducing Waste with Smart Frying | Implement batch frying to minimize oil absorption and maintain stable temperatures. |

Eco-Friendly Oil Disposal | Ensure proper disposal of used oil to prevent environmental damage. |

Devices like the Frylow can help you fry at lower temperatures, saving energy and producing healthier food.

Advanced filtration systems reduce impurities, making your fryer more efficient and your food more appealing.

For energy-efficient fryers and accessories, explore the options at Stabake Food Machine.

Achieving consistent results in your kitchen depends on both your equipment and your process. When you use advanced deep frying equipment, you can control every step and produce the same high-quality food every time. This section will show you how standardization and recipe adjustments help you get the best results, whether you run a restaurant or cook at home.

Standardizing your frying process helps you control the variables that affect food quality. When you use a modern fryer, like those from Stabake Food Machine, you can store multiple cooking programs. These programs let you set exact times and temperatures for each menu item. Features such as load compensation and proportional control adjust cooking parameters automatically, so every batch comes out just right.

Standardized procedures optimize food quality by controlling key variables.

Advanced fryers store cooking programs for precise control.

Automatic adjustments ensure consistency, no matter the batch size.

Equipment programs simplify your workflow and reduce mistakes.

You can see how quality control measures support batch control in the table below:

Quality Control Measure | Description |

|---|---|

Fryer Maintenance | Regular maintenance keeps your fryer working well and prevents oil problems. |

Oil Management | Proper oil loading, circulation, and heating maintain food quality. |

Filtration Systems | Crumb removal screens and filtration systems keep oil clean and fresh. |

You should also follow these steps for better batch control:

Start oil loading, circulation, and heating before you begin frying.

Sanitize your fryer after each shift.

Remove food particles to prevent oil degradation.

Quality checks make sure every batch meets your standards. You need to check oil quality, monitor cooking times, and inspect food appearance. Many advanced fryers alert you when oil needs changing or when a batch is ready. You should also follow food safety programs like HACCP and GMP to keep your kitchen safe and compliant.

Tip: Consistent quality checks help you build a strong reputation for your fried foods.

Precise temperature control is essential for great frying results. Different foods need different oil temperatures. For example, tempura cooks best at 340-360°F, while yeast donuts need 365°F and cake donuts require 375°F. If you fry delicate items like shrimp, you should use lower temperatures to protect their texture. Advanced fryers from Stabake Food Machine let you set and hold exact temperatures, so you never have to guess.

Use the right temperature for each food to get the best color and crunch.

Adjust settings for each recipe to avoid undercooking or burning.

Ingredients also affect your results. When you try new deep-frying recipes, you may need to adjust the temperature or cooking time. For homemade fried chicken, you want a crispy crust and juicy meat. You can achieve this by using the right oil, seasoning, and batter, and by setting your fryer to the correct temperature. Ingredient changes, like using gluten-free flour or different oils, may require you to tweak your process for the best outcome.

Note: Experiment with small batches when you change ingredients or recipes. This helps you find the perfect settings for your fryer.

By standardizing your process and making smart recipe adjustments, you can deliver delicious, consistent fried foods every time.

Advanced deep frying equipment helps you achieve faster cooking, consistent results, and safer operations. You improve productivity by selecting the right fryer, optimizing your workflow, and using technology like smart controls and oil filtration. Regular maintenance and expert reviews guide your choices. Explore product catalogs such as Stabake Food Machine for reliable options.

Actionable Step | Benefit |

|---|---|

Implement Oil Filtration | Maintains clean oil and reduces replacement costs |

Schedule Regular Filtration | Maximizes frying efficiency and oil quality |

Use Auto Filter Process | Saves time and improves oil quality |

You should check for precise temperature control, large basket capacity, and built-in oil filtration. These features help you cook faster and keep food quality high. Explore Stabake Food Machine for models with these options.

You should clean your fryer daily. Remove food particles, filter the oil, and wipe down surfaces. Weekly deep cleaning keeps your equipment safe and efficient.

Tip: Regular cleaning prevents clogs and keeps your food tasting fresh.

You can use small commercial fryers at home if you have enough space and proper ventilation. Compact models from Stabake Food Machine fit home kitchens and offer professional results.

Oil filtration removes crumbs and debris, keeping oil clean. Clean oil cooks food faster and tastes better. You save money by replacing oil less often.

Benefit | Description |

|---|---|

Faster Cooking | Clean oil heats quickly |

Better Taste | No burnt flavors |

Cost Savings | Less oil replacement |

You should look for automatic shut-off, cool-touch exteriors, and secure lids. Overheat protection and non-slip feet also help prevent accidents.

You should pick electric fryers for easy cleaning and fast temperature recovery. Gas fryers work best for high-volume cooking and lower energy costs. Compare models at Stabake Food Machine.

You should inspect heating elements, clean baskets, and check thermostats regularly. Keep spare parts on hand for quick fixes. Schedule professional service for deep cleaning and repairs.

You can find trusted commercial and home fryers at Stabake Food Machine. Read expert reviews and compare features before buying.