Views: 0 Author: Site Editor Publish Time: 2025-09-23 Origin: Site

A Food Packaging Machine helps you automate the packaging process, making your operation faster and more reliable. You protect your food products by ensuring every packaging step meets strict hygiene standards. Automation also reduces the need for manual labor, which helps keep your packaging area clean and safe. According to industry research, 68% of users plan to invest in machines that focus on food safety and compliance.

Evidence Point | Description |

|---|---|

Sanitation in Design | Food safety and sanitation are fundamental in packaging design, influencing manufacturing processes and machine design. |

Automation Reduces Labor | Automation is crucial in addressing labor shortages, enhancing sanitation processes by minimizing reliance on manual labor. |

Demand for Compliance | A significant percentage of end users (68%) plan to invest in food-safety compliant machinery, indicating a strong market trend towards automation and safety. |

You gain efficiency, improve packaging consistency, and meet the growing demand for safe, well-sealed packaging in today’s food industry.

When you explore the types of food packaging machines, you discover a wide range of solutions designed for different products and packaging needs. Stabake Food Machine offers a diverse catalog, including machines for bakery, fruit and vegetable, meat and fish, and general food packing.

Category | Link |

|---|---|

Bakery and Pastry Processing Machine | |

Food Packing Machine |

You use vertical form fill seal machines to package a variety of products quickly and efficiently. These machines form bags from a roll of film, fill them with product, and seal them—all in a vertical motion.

Vertical form fill seal machines work well for grains, snacks, cereals, frozen foods, bakery products, and powdered products. You can package coffee, pet food, and specialty items with output rates reaching up to 260 packs per minute for dry and liquid foods.

Food Product Type | Output Rate (ppm) | Machine Type |

|---|---|---|

Coffee | Up to 180 | Intermittent VFFS |

Dry and Liquid Food | Up to 260 | Continuous motion VFFS |

Pet Food | Up to 180 | Intermittent VFFS |

Specialty Products | Up to 180 | Intermittent VFFS |

Frozen Food | High-speed | Continuous motion VFFS |

Powdered Products | N/A | Continuous motion VFFS |

You benefit from packaging that keeps products fresh, extends shelf life, and provides accurate portion control. If you want to see more options, check out the Food Packing Machine section in the Stabake catalog.

Horizontal flow wrap machines help you package bakery and confectionery items with speed and precision. These machines wrap products in a continuous film, seal the edges, and cut them into individual packs.

You operate in a controlled environment, which minimizes human contact and reduces contamination risks.

You can package irregular, soft, or fragile items with airtight seals that protect against moisture and dust.

Advantage | Description |

|---|---|

Continuous film feed | Ensures uninterrupted packaging |

Airtight sealing | Extends shelf life of products |

Compatibility with various products | Suitable for irregular, soft, or fragile items |

Flexibility in pack sizes | Can accommodate multiple packaging styles and sizes |

You get flexibility in pack sizes and styles, making horizontal flow wrap machines ideal for bakery and pastry products. Explore the Bakery and Pastry Processing Machine catalog for more solutions.

Vacuum packaging machines remove air from the package before sealing, which helps you extend the shelf life of perishable foods.

You keep food safe by removing oxygen, which spoilage organisms need to grow.

You prevent oxidative spoilage and discoloration.

The anaerobic environment stops bacteria and fungi from multiplying.

Vacuum packaging acts as a barrier to dust, moisture, and contaminants.

You extend shelf life up to five times longer than traditional packaging.

You preserve the original flavor and texture.

You reduce oxidation and freezer burn.

Vacuum sealing creates durable packaging that protects products from external elements and keeps perishables fresh. For meat, fish, and other sensitive foods, visit the Meat and Fish Processing Machine catalog.

You use tray sealing machines to package foods in rigid trays, which helps keep products fresh and safe. This type of packaging machine works well for ready-to-eat meals, fresh produce, sweets, and frozen items. Tray sealing creates a tight seal over the tray, locking in freshness and preventing leaks or contamination. You can choose from different models to match your production needs.

Machine Model | Sealing Speed (trays/hour) | Common Food Products |

|---|---|---|

HHA600 | 7200 | Fresh produce, ready-to-eat meals |

AL300X | Adjustable | Rigid plastic lids, overwrapping |

MiniMatic III | Constant | Intermediate volume packaging |

HCSA100 | Hundreds | Various rigid trays |

HCM100 | Hundreds | Various rigid trays |

AL400 | Hundreds | Plastic and paperboard tray styles |

ATS Models | Finesse | Sweets, cakes, ready-to-eat foods, frozen items |

You benefit from high-speed sealing, which increases your output and reduces labor costs. Tray sealing machines handle a wide range of tray materials, including plastic and paperboard. You can explore more options in the Food Packing Machine section of the Stabake catalog.

Filling and capping machines help you package liquids, sauces, and semi-liquids with accuracy and speed. These machines fill containers to precise levels and then cap them securely. You maintain product quality and prevent contamination by using automated systems that meet strict hygiene standards.

Aspect | Description |

|---|---|

Precision Filling | Machines ensure fill volumes within a tolerance of ±1%, minimizing waste and ensuring consistency. |

Consistent Quality | Automation maintains consistent fill volumes and secure seals, crucial for regulatory compliance. |

Regulatory Compliance | Designed to meet GMP and FDA guidelines, ensuring safety and quality standards are adhered to. |

Focus on Hygiene and Safety | Capping machines meet stringent hygiene standards to prevent contamination during sealing. |

You rely on these machines for dairy, beverages, sauces, and oils. Filling and capping machines support your compliance with food safety regulations. You can find suitable machines for your operation in the Food Packing Machine catalog.

Labeling and coding machines give you the tools to track and trace every package. You apply labels and print codes that show important information, such as expiration dates and batch numbers. These machines use advanced technologies to ensure your packaging meets food safety rules and traceability standards.

Technology Type | Description |

|---|---|

Continuous Inkjet (CIJ) | Used for printing high-quality codes on various packaging materials. |

Thermal Inkjet (TIJ) | Provides flexible printing options for traceability codes. |

Thermal Transfer Overprinting (TTO) | Ensures high-quality, machine-readable codes. |

Laser Marking | Offers permanent marking solutions for traceability. |

Large Character Printers | Suitable for printing large codes on packaging. |

Labelers | Used for applying labels with traceability information. |

VideojetConnect™ Software | Integrates traceability codes with key data elements and enterprise systems. |

Videojet CLARiSUITE® | Manages data logs for traceability records and compliance. |

Operator Training | Ensures consistent code quality and regulatory compliance. |

Customized Service Plans | Aims to minimize downtime and maximize equipment performance. |

Barcode scanning lets you track items at each step.

RFID tags help you read package data remotely.

Blockchain technology keeps product information secure and transparent.

IoT sensors monitor temperature and humidity for perishable goods.

You can choose labeling and coding machines that fit your needs from the Food Packing Machine catalog. These machines help you meet food industry standards and keep your products safe and traceable.

You encounter specialized machines when you need to solve unique packaging challenges in your food production line. These machines handle tasks that standard equipment cannot manage, giving you more control over product quality and presentation. Specialized machines support a wide range of foods, including ready-to-eat meals, dairy products, fresh produce, and dry goods. You can select the right solution for liquids, powders, and solids, which adds versatility to your operation.

Specialized machines help you meet strict hygiene standards and improve packaging efficiency. You reduce spoilage and contamination risks by automating complex tasks.

Here are some examples of specialized food packaging machines and their unique functions:

Machine Type | Unique Functions |

|---|---|

Thermoforming Packaging | Packages ready-to-eat meals, fresh produce, and dairy products while ensuring freshness and cleanliness. |

Case Packing | Automates grouping products into cases for secure transportation, reducing spoilage and contamination. |

Cartoning | Creates cartons for various food products, ensuring speed, accuracy, and consistent quality. |

Flow Wrapping | Wraps products in protective film, extending shelf life and maintaining freshness. |

Vacuum Packaging | Removes air to create airtight packages, significantly reducing spoilage risk. |

Form-Fill-Seal | Packages dry goods, liquids, and perishable items using modified atmosphere packaging techniques. |

You use thermoforming packaging machines when you want to keep meals and produce fresh for longer periods. These machines shape trays or containers from plastic sheets, fill them with food, and seal them tightly. You maintain cleanliness and extend shelf life.

Case packing machines help you group products into boxes or cases for shipping. You automate this step to protect items during transport and reduce the chance of damage or contamination. You save time and lower labor costs.

Cartoning machines create cartons for foods like cereals, snacks, and frozen items. You benefit from fast, accurate, and consistent packaging that improves your brand’s presentation.

Flow wrapping machines wrap products in a continuous film. You use these machines for items that need extra protection from moisture and air. You keep products fresh and attractive on store shelves.

Vacuum packaging machines remove air from packages, which helps you prevent spoilage and maintain food safety. You rely on these machines for meats, cheeses, and other perishables.

Form-fill-seal machines use modified atmosphere techniques to package dry goods, liquids, and perishable items. You adjust the atmosphere inside the package to slow down spoilage and keep products fresh.

You find many specialized machines in the Stabake Food Machine product catalog. If you want to explore more options for your operation, visit the Food Packing Machine section. You can choose machines that match your production needs and help you achieve high standards in packaging.

You start the packaging process by feeding and loading your product and packaging materials into the food packaging machine. Most modern machines use a continuous reel of film or pre-made containers. The machine unwinds the film and positions it for the next steps. You can load products like powders, liquids, or solids using hoppers, conveyors, or vibratory feeders. This step ensures a steady supply of both product and packaging material, which keeps your operation running smoothly.

Automation in feeding and loading reduces manual labor and increases efficiency. You see fewer errors and less waste because the machine handles the materials with precision.

You can find machines designed for different products in the Stabake Food Packing Machine catalog. These machines help you handle a wide range of foods, from snacks to sauces.

After loading, the packaging machine forms the package from the reel-fed material. The film unwinds and wraps around a forming tube or mold, creating a pouch or container. The machine shapes the film into a tube, then seals the edges to create a secure package. This method supports many packaging types, such as bags, pouches, and trays.

Here is a typical sequence for forming packages:

The machine unwinds the film from the reel.

The film passes over a forming collar or tube.

The machine shapes the film into a tube or tray.

The edges are sealed to create a pouch or container.

This automated process allows you to produce packages quickly and consistently. You benefit from high-speed production, lower labor costs, and improved product protection. The automation also reduces human error, which means you get uniform packaging every time.

Once the package is formed, the next step is filling. Filling machines dispense the right amount of product into each package. You can use different filling systems depending on your product type. For liquids, the machine considers viscosity and temperature to ensure accurate filling. For powders and free-flowing solids, auger fillers or volumetric cup systems deliver precise amounts. If you work with very fine powders, vacuum fillers prevent dust and spillage.

Accurate filling is essential for product protection and consistency. Automated filling machines help you minimize waste and maintain quality.

You can rely on automated filling to keep your packaging process fast and reliable. The machine fills each package with the same amount, which improves product appearance and customer satisfaction. You can explore different filling machines in the Stabake catalog to match your specific needs.

Standard Steps in the Packaging Process:

Film unwind and forming

Product filling

Sealing and cutting

Product discharge

Quality control and inspection

Secondary operations, such as labeling

By following these steps, you achieve efficient packaging, improved product protection, and consistent results.

You rely on sealing machines to create secure closures that keep your food fresh and safe. During the packaging process, sealing is a critical step that prevents air, moisture, and contaminants from entering the package. You choose from several sealing methods, each offering unique benefits for different food types and packaging materials.

Sealing Method | Materials | Advantages | Applications |

|---|---|---|---|

Heat Sealing | Plastic films, foils | Cost-effective, versatile | Snacks, ready meals |

Vacuum Sealing | Rigid, flexible packaging | Extends shelf life, prevents spoilage | Meats, cheese, seafood |

Ultrasonic Sealing | Composite films, plastic | Seals through residue, energy-efficient | Fresh produce, salads |

Induction Sealing | Bottles, cans | Tamper-evident, leak-proof | Canned foods, beverages |

Tray Sealing | Rigid trays, plastic films | Secure, MAP-compatible | Ready meals, frozen foods |

Skin Packaging | Cardboard, rigid trays | Extended freshness, clear display | Fresh meats, seafood |

Pressure-Sensitive | Jars, bottles | Quick, tamper-evident | Dry goods, cosmetics |

Cap & Closure Sealing | Bottles, cans | Leak-proof, tamper-evident | Canned foods, drinks |

Resealable Sealing | Plastic bags, zipper bags | Reusable, reduces waste | Snacks, spices |

Stretch Sealing | Plastic films, rigid trays | Leak-proof, clear display | Poultry, meats |

You improve product protection and extend shelf life by selecting the right sealing method for your packaging machine. Heat sealing forms airtight seals on pouches, while vacuum sealing removes air to slow spoilage. Ultrasonic sealing works well when you need to seal through residue, and induction sealing creates tamper-evident closures for liquids. Each method supports efficiency and safety in your packaging process.

If you want to explore sealing machines for your operation, you can find options in the Stabake Food Packing Machine catalog. These machines help you maintain high standards for food safety and freshness.

After sealing, you use cutting and shaping mechanisms to give each package its final form. This step ensures that every package looks uniform and meets quality standards. You benefit from automated systems that cut and shape packaging materials with precision.

Rotary machines deliver consistent package shapes and sizes, which helps you maintain a professional appearance.

Automated control systems check each package for defects, so you avoid irregularities and reduce waste.

Customizable program settings let you adjust the process for different products and materials, which minimizes errors.

Automated quality checks catch problems early, so you only send out packages that meet your standards.

Feature | Contribution to Uniformity and Waste Reduction |

|---|---|

Precision cutting and sealing | Ensures consistent package design and sealing quality, reducing variability in product presentation. |

Automated control systems | Maintains consistent package quality through high accuracy, preventing irregularities. |

Customizable program settings | Tailors operations based on product size and material type, minimizing errors and waste. |

Automated quality checks | Detects defects during production, ensuring each item meets standards. |

You see improved product protection and cost savings because these mechanisms reduce material waste and labor needs. The packaging process becomes more efficient, and your brand benefits from uniform, attractive packages. If you need machines with advanced cutting and shaping features, you can review the Stabake Food Packing Machine catalog for solutions that match your requirements.

Labeling is the final step in the packaging process. You use labeling machines to apply labels and print codes on each package. These labels show important information, such as expiration dates, batch numbers, and product details. You help customers make safe choices and meet food safety regulations by providing clear and accurate labels.

You can use barcode scanners, RFID tags, and IoT sensors to track your products and monitor conditions like temperature and humidity. These technologies support traceability and compliance in your packaging operation.

Labeling machines work with many packaging types, including bottles, jars, pouches, and trays. You select machines that fit your production speed and labeling needs. If you want to upgrade your labeling process, you can find reliable machines in the Stabake Food Packing Machine catalog.

Labeling not only improves safety and traceability but also enhances your brand’s presentation. You build trust with customers by making sure every package has the right information.

You rely on a packaging machine to keep your food safe during storage and transport. Packaging acts as a shield against damage, spoilage, and contamination. When you use high-quality packaging, you prevent food from deteriorating and keep it fresh for longer periods. The materials in packaging protect your products from breaking and stop harmful substances from reaching the food. You also reduce the risk of expired food, which can cause health problems.

Packaging machines serve several important roles in product protection. They seal food tightly, blocking out oxygen and moisture that can lead to spoilage. You avoid mechanical damage because the packaging holds the food securely. The machine also helps you guard against biological hazards, such as bacteria and mold. By using the right packaging, you make sure your food stays safe and undamaged throughout its journey from your facility to the customer.

If you want to explore machines that offer strong protection for your products, you can review options in the Stabake Food Packing Machine catalog. These machines help you maintain food quality and safety at every step.

You must meet strict hygiene and safety standards when packaging food. Packaging machines help you follow industry regulations and keep your products safe for consumers. The design of these machines supports clean operations and reduces the risk of contamination. You benefit from features like easy-to-clean surfaces, automated controls, and safe materials.

Here is a table showing key compliance standards and measures that packaging machines help you achieve:

Compliance Standard | Key Measures |

|---|---|

Food Safety Modernization Act (FSMA) | Preventive controls, hazard analysis, supply chain management |

Good Manufacturing Practices (GMP) | Facility design, personnel hygiene, documentation |

Packaging Materials Regulations | Safe materials, migration limits, testing |

International Standards | ISO 22000, NSF/ANSI 3-A 14159-1, European Machinery Directive |

Electrical Safety Standards | Proper wiring, electrical component safety, compliance testing |

You use packaging machines that meet these standards to ensure your food stays safe from production to delivery. The machines help you control hazards, maintain clean facilities, and use safe materials. You also follow international guidelines, which makes your products trusted in the market.

You improve your operation’s efficiency when you use automated packaging machines. These machines help you work faster and reduce mistakes. You identify bottlenecks and fix them, which leads to better workflow and equipment use. You also anticipate breakdowns with predictive maintenance, so you avoid unexpected downtime.

Optimized operations let you use your equipment more effectively.

Predictive maintenance helps you keep machines running smoothly.

Enhanced quality control allows you to spot problems quickly and reduce waste.

Improved inventory management gives you real-time data to prevent shortages or excess stock.

Reduced costs come from saving materials and energy.

Better decision making happens when you use data-driven insights.

You see these benefits when you choose the right packaging machine for your needs. Automated systems help you package food quickly, maintain quality, and lower your costs. If you want to boost your efficiency, you can find suitable machines in the Stabake Food Packing Machine catalog.

You can achieve significant cost savings when you use a packaging machine in your food production line. Automation helps you reduce labor costs because machines handle repetitive tasks that would otherwise require many workers. You spend less on wages and training, and you also avoid costs related to human error, such as product recalls or rework.

Packaging machines improve efficiency, which means you can produce more packages in less time. Faster production lets you fulfill orders quickly and meet customer demand. You also see savings in material use because automated systems measure and dispense precise amounts, minimizing waste. Many machines support eco-friendly materials, which appeals to environmentally conscious customers and can lower disposal costs.

Investing in energy-efficient machinery helps you save money on energy bills over time. Streamlined operations through lean manufacturing practices eliminate unnecessary steps and reduce waste.

Here are some ways packaging machines help you save money:

Automating tasks reduces labor costs and the need for extensive training.

Machines use materials efficiently, so you waste less packaging.

High-speed production lowers labor costs and increases output.

Tray sealing machines extend shelf life, which reduces food spoilage and the costs that come with it.

Automated case packing saves on labor and reduces product damage during transport.

Energy-efficient machines lower your utility bills.

You can find machines designed for cost savings in the Stabake Food Packing Machine catalog. These machines help you optimize your workflow and maximize your return on investment. When you choose the right equipment, you improve product protection and reduce expenses across your operation.

Modern packaging machines offer you a wide range of customization options. You can tailor machines to fit different product shapes and sizes, which gives you flexibility in your packaging process. Adjustments for product sizes let you switch between small snack packs and large trays without major changes to your equipment.

Customization Aspect | Description |

|---|---|

Adjustments for Product Sizes | Machines can be tailored to accommodate various product sizes, ensuring versatility in packaging. |

Unique Product Shapes | Capable of handling products with unique shapes, enhancing packaging flexibility. |

Specific Sealing Methods | Custom sealing methods can be implemented to meet specific product requirements. |

You benefit from tool-free changeovers, which allow you to adjust your packaging machine quickly for different products. Servo-driven grippers keep your operation stable at high speeds, so you maintain efficiency even when switching between items. Pouch packing machines handle a wide range of sizes and materials, making them ideal for ready-to-eat foods, snacks, and specialty items.

Many manufacturers offer options to customize machines for your specific needs. You can request custom-sized packaging or features that handle unique product shapes. This level of customization ensures your packaging process runs smoothly and supports product protection for every item you produce.

If you want to explore machines with advanced customization features, you can visit the Stabake Food Packing Machine catalog. These solutions help you meet your production goals and adapt to changing market demands.

You achieve remarkable consistency in your food packaging process when you use automated systems. Machines operate without fatigue or distraction, so every package looks the same and meets your standards. You avoid mistakes like incorrect fills or misaligned labels, which often happen with manual work. Built-in sensors and quality controls catch errors right away, so you can fix problems before products leave your facility.

Evidence Type | Description |

|---|---|

Human Error | Mistakes such as incorrect fills and misaligned labels are reduced with automation. |

Consistent Operation | Machines operate without fatigue or distraction, ensuring uniformity in packaging. |

Built-in Quality Controls | Automated systems include sensors and checks that catch errors immediately. |

Standardization | Automation leads to fewer variations, ensuring each unit meets specifications. |

Reduced Contamination Risk | Less human handling decreases the chances of cross-contamination. |

Logistics & Traceability | Integrated data systems ensure accurate tracking, reducing errors in shipping and recalls. |

Consistency Through Automation | Automated machinery provides a level of consistency unattainable through manual processes. |

You build trust with your customers because they know what to expect every time they buy your product. Consistent packaging also helps you meet regulatory requirements and maintain your brand reputation. If you want to see machines that offer reliable performance, you can explore options in the Stabake Food Packing Machine catalog.

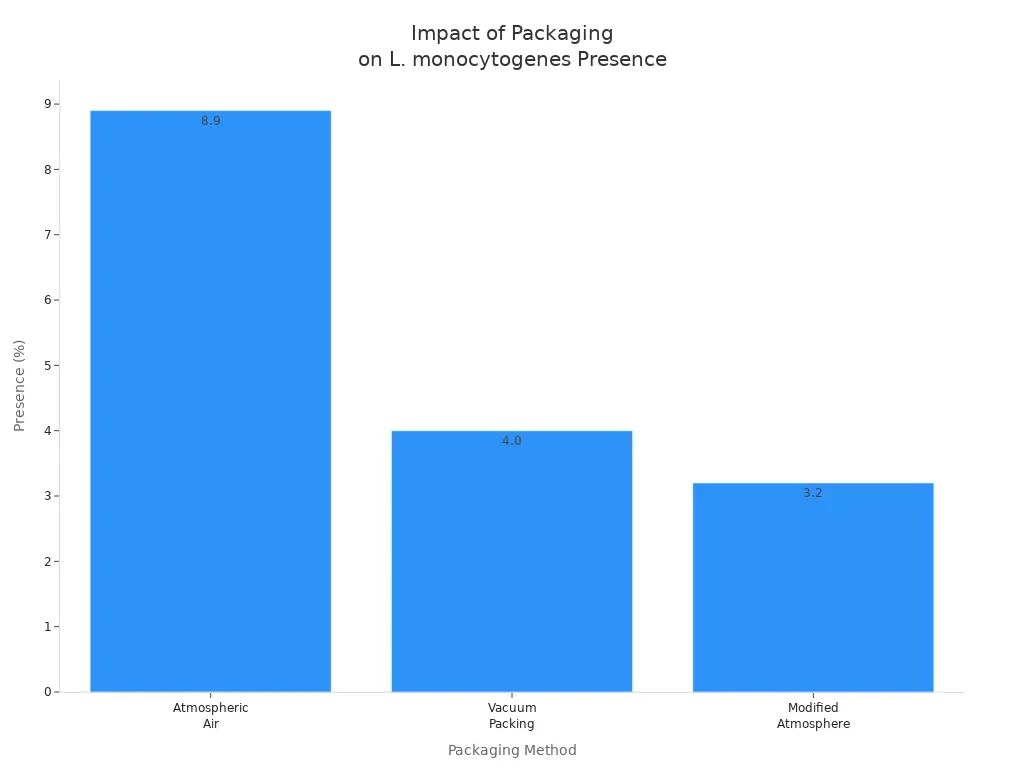

You extend the shelf life of your food products by choosing the right packaging method. Packaging machines help you seal products tightly, keeping out air and moisture that cause spoilage. Scientific studies show that vacuum packing and modified atmosphere packaging (MAP) reduce the presence of harmful bacteria and slow down mold growth.

Packaging Method | Presence of L. monocytogenes | Spoilage Factors |

|---|---|---|

Atmospheric Air | 8.9% | Growth of yeast and mould |

Vacuum Packing | 4.0% | Growth of LAB (Enterococcus, etc.) |

Modified Atmosphere (MAP) | 3.2% | Not specified in the study |

You keep your products fresh longer, which means less waste and happier customers. Airtight seals and advanced packaging techniques protect food from spoilage and contamination. You can find machines designed for vacuum packing and MAP in the Stabake catalog, helping you deliver safe and long-lasting products.

You make your products stand out on store shelves with professional packaging. Automated machines create packages with clear window panels, colorful foils, and transparent films. These features let customers see the product inside, which builds trust and encourages purchases. Uniform size, weight, and appearance give your brand a polished look.

You boost consumer appeal by using packaging that looks attractive and keeps food fresh. Airtight seals preserve flavor and texture, so customers enjoy your products at their best.

You can choose packaging machines that support creative designs and consistent presentation. When you use advanced technology, you show your commitment to quality and freshness. If you want to improve your brand image, explore the Stabake Food Packing Machine catalog for solutions that match your vision.

You want your food business to grow without facing constant equipment changes. Automated packaging machines help you scale up production with ease. When demand increases, you can adjust your packaging process instead of buying new machines. This flexibility supports your business as it expands.

Automated machines adapt to higher production volumes. You do not need major modifications when your orders grow.

You can add new modules, such as capping or labeling systems, as your business expands. This approach saves you from purchasing entirely new equipment.

You adjust or upgrade your automated packaging systems to handle new packaging formats, materials, or product sizes. This ability keeps your operation efficient as your product line grows.

Modular designs and customization options give you long-term value. You avoid frequent reinvestment and keep your packaging process flexible.

When you use a packaging machine with modular features, you respond quickly to market changes. You can switch between different packaging styles or sizes without slowing down production. This adaptability helps you meet customer needs and stay competitive.

Many solutions in the Stabake Food Packing Machine catalog offer modular upgrades and customization. You choose machines that match your current needs and expand them as your business grows. This strategy supports efficient packaging and helps you control costs over time.

Tip: Choose a packaging machine with modular options if you plan to introduce new products or expect seasonal spikes in demand. This choice gives you the flexibility to grow without major disruptions.

You must follow strict food safety and labeling regulations to protect your customers and your brand. Packaging machines help you meet these requirements by automating critical steps in the packaging process. You reduce errors and ensure every package meets industry standards.

Evidence Type | Description |

|---|---|

Accuracy in Labeling | Automated labeling machines ensure consistent accuracy, reducing errors that could lead to compliance issues. |

Allergen Information | Proper labeling of allergens is crucial for consumer safety and compliance, preventing serious health risks. |

Regulatory Information | Labels must include expiration dates and traceability information, which are essential for safety and compliance. |

Automated labeling systems apply labels with precision. You avoid mistakes that could result in recalls or fines. Accurate allergen information keeps consumers safe and helps you comply with regulations. Including expiration dates and traceability details on every package supports food safety and makes recalls easier if needed.

You benefit from packaging machines that support compliance with local and international standards. Many machines in the Stabake Food Packing Machine catalog offer advanced labeling and coding features. You maintain high standards and build trust with your customers by using reliable packaging technology.

Note: Regularly review your packaging process to ensure your machines meet the latest regulatory requirements. Upgrading your equipment helps you stay ahead of changes in food safety laws.

You must consider the type of food product before choosing a packaging machine. Different foods require unique packaging solutions. Dry goods like rice or pasta need packaging that keeps moisture out. Liquids such as juices or sauces demand leak-proof containers. Fragile items like pastries or chips benefit from packaging that cushions and protects them during transport.

You should match your packaging machine to your product’s characteristics. For example, vertical form fill seal machines work well for grains and powders. Horizontal flow wrap machines suit bakery items. Vacuum packaging is ideal for meats and seafood. If you package ready-to-eat meals, tray sealing machines offer secure and attractive presentation.

Tip: Visit the Stabake Food Packing Machine catalog to find machines designed for your specific product type.

You need to check if your packaging machine works with the materials you plan to use. Packaging materials include plastic films, paperboard, aluminum foil, and rigid trays. Each material has different sealing and forming properties. Some machines handle flexible films, while others work with rigid containers.

You should select packaging materials that protect your food and meet safety standards. For example, plastic films provide airtight seals for snacks and frozen foods. Paperboard trays suit bakery and confectionery products. Aluminum foil offers strong barriers for dairy and ready meals.

Here is a table showing common packaging materials and their compatibility with machine types:

Packaging Material | Compatible Machine Types | Typical Food Products |

|---|---|---|

Plastic Film | VFFS, Flow Wrap, Vacuum | Snacks, frozen foods |

Paperboard | Tray Sealing, Cartoning | Bakery, confectionery |

Aluminum Foil | Tray Sealing, Vacuum Packaging | Dairy, ready meals |

Rigid Trays | Tray Sealing, Thermoforming | Ready-to-eat meals |

You improve food safety and shelf life by choosing the right combination of machine and material.

You want your packaging process to run quickly and efficiently. Speed affects how many products you can package in a given time. High-speed machines help you meet large orders and reduce labor costs. You should look for machines with adjustable speed settings to match your production needs.

Some packaging machines process hundreds of packages per minute. For example, vertical form fill seal machines can reach up to 260 packs per minute for dry foods. Tray sealing machines handle dozens of trays every hour. You should balance speed with accuracy to avoid mistakes and waste.

Note: Faster machines may require more maintenance and skilled operators. You should consider your team’s experience and your production goals before choosing a high-speed solution.

If you need help selecting a machine with the right speed for your operation, check the Stabake Food Packing Machine catalog. You can find models that fit small businesses and large factories.

You need to keep your packaging machine in top condition to ensure reliable performance and long equipment life. Regular maintenance helps you avoid unexpected breakdowns and costly repairs. When you follow a maintenance schedule, you keep your packaging process running smoothly and protect your investment.

Start by cleaning your machine every day. Remove food particles, dust, and debris from all surfaces. This step prevents contamination and keeps your packaging safe for consumers. Lubricate moving parts as recommended by the manufacturer. Proper lubrication reduces friction and wear, which helps your machine last longer.

Check for worn or damaged parts each week. Replace belts, seals, and blades before they fail. Inspect electrical connections and sensors to make sure they work correctly. If you notice any unusual noises or vibrations, stop the machine and investigate the cause.

Tip: Keep a maintenance log. Record every inspection, cleaning, and repair. This log helps you track issues and plan for future service.

Here is a simple maintenance checklist you can follow:

Clean all surfaces and remove debris after each shift.

Lubricate gears, bearings, and chains as needed.

Inspect belts, seals, and blades for signs of wear.

Test sensors and safety switches.

Check electrical connections for loose wires.

Replace worn parts before they cause problems.

Review the maintenance log weekly.

You can find packaging machines with easy-to-clean designs and tool-free access in the Stabake Food Packing Machine catalog. These features make routine maintenance faster and safer.

When you keep your packaging equipment well-maintained, you reduce downtime and improve product quality. You also extend the life of your machine, which saves you money over time. Good maintenance practices help you deliver safe, high-quality packaging to your customers.

You want your packaging machine to work seamlessly with other equipment in your production line. Integration means connecting your packaging system with conveyors, filling machines, labeling units, and inspection devices. When you achieve smooth integration, you boost efficiency and reduce manual handling.

Start by choosing machines that support standard communication protocols. Many modern packaging systems use PLCs (Programmable Logic Controllers) or Ethernet connections. These technologies let your machines share data and coordinate actions.

Note: Integrated systems help you monitor production in real time. You can spot bottlenecks and adjust settings quickly.

Here are some benefits of integrating your packaging equipment:

Faster production flow with fewer stops.

Better tracking of products through each stage.

Easier quality control and data collection.

Lower risk of errors from manual transfers.

You should plan your integration before you buy new machines. Make sure your packaging machine matches the speed and size of your other equipment. Ask your supplier about compatibility and support for integration. The Stabake Food Packing Machine catalog offers solutions designed for easy integration with existing lines.

When you integrate your packaging system, you create a more efficient and reliable operation. You save time, reduce labor costs, and improve the consistency of your packaging. This approach helps you meet production goals and deliver high-quality products to your customers.

You start by assessing your needs before selecting a packaging machine. You look at your product and decide what type of packaging works best. You consider the size, shape, and texture of your food items. You also think about how much product you want to package each day. If you produce snacks, you may need a machine that handles small, lightweight packages. If you package liquids, you look for equipment that prevents leaks and keeps your product fresh.

You ask yourself these questions:

What is the main product you want to package?

How many units do you need to package per hour or day?

Do you need special features, such as vacuum sealing or labeling?

What are your hygiene and safety requirements?

You can explore the Stabake Food Machine product catalog to find machines that match your needs. The catalog offers solutions for bakery, meat, produce, and more.

You compare different types of packaging machines to find the best fit for your operation. You look at how each machine works and what products it handles. Vertical form fill seal machines work well for grains and powders. Horizontal flow wrap machines suit bakery and confectionery items. Vacuum packaging machines help you extend shelf life for meats and seafood. Tray sealing machines are ideal for ready-to-eat meals and fresh produce.

You make a list of features for each machine type:

Speed and output rates

Compatibility with packaging materials

Ability to handle different product shapes and sizes

Options for labeling and coding

You match your product needs to the machine features. You choose a machine that supports your production goals and keeps your food safe.

You think about cost when choosing a packaging machine. You look at the price of the machine and the cost of maintenance. You also consider how much you will spend on packaging materials. You want a machine that fits your budget but also meets your quality standards.

Here are important factors to consider:

Product characteristics influence the technology you need.

Throughput requirements affect your choice of machine.

Efficiency ensures consistent performance and output.

Cleanability is vital for food safety.

Parts and service availability minimize downtime.

Tip: You save money in the long run by choosing a machine that is easy to clean and maintain. You also benefit from reliable support and access to replacement parts.

You can consult the Stabake Food Machine catalog for tailored solutions that balance cost and performance. This approach helps you make a smart investment for your packaging operation.

When you choose a packaging machine, you need to think about the support and service you will receive from your supplier. Good support helps you solve problems quickly and keeps your packaging process running smoothly. You want a supplier who stands behind their products and helps you succeed.

You should look for a supplier with a strong reputation in the industry. Reliable suppliers deliver machines on time and provide consistent service. You can check customer reviews and testimonials to see how other businesses rate their experience. Awards and certifications show that a supplier cares about quality and has a strong market presence.

Customer support plays a big role in your daily operations. You need help when you face technical issues or have questions about your packaging machine. Fast and friendly support makes your job easier and helps you avoid long delays. Some suppliers offer training for your team, so everyone knows how to use the equipment safely and efficiently.

Modern packaging requires advanced technology. Suppliers with strong technological capabilities can offer machines that improve your efficiency and help you stay ahead in the market. You want a partner who updates their products and provides solutions that match your needs.

Here is a table showing important criteria for evaluating support and service:

Criteria | Description |

|---|---|

Supplier Reliability | Ensures timely delivery and consistent service; assess through customer reviews and testimonials. |

Industry Reputation | Reflects commitment to excellence; check for awards, certifications, and market presence. |

Customer Support | Availability of support and responsiveness to issues; important for long-term partnership. |

Technological Capabilities | Ability to provide cutting-edge technologies that enhance operational efficiency. |

You can find suppliers who meet these standards in the Stabake Food Machine product catalog. Stabake offers a wide range of packaging solutions and provides strong support for their customers. You can visit their Food Packing Machine catalog to learn more about their products and services.

Tip: Choose a supplier who offers training, fast response times, and easy access to spare parts. This choice helps you keep your packaging line running without interruptions.

Food packaging machines help you automate every step, from forming and filling to sealing and labeling. You improve food safety, boost efficiency, and deliver consistent results. Automation reduces errors and keeps your products fresh.

To find the best solution for your business, review your needs and explore expert options.

You can visit the Stabake Food Packing Machine catalog for reliable machines and expert advice.

You start by identifying your product type and daily output. You compare machine features, speed, and compatibility. You visit the Stabake Food Packing Machine catalog for tailored solutions that match your needs.

You clean the machine daily and inspect moving parts each week. You replace worn components before they fail. You follow the manufacturer’s maintenance schedule to keep your equipment running smoothly and safely.

You find machines designed for solids, liquids, and powders. You adjust settings for each product. You select specialized equipment from the Stabake Food Packing Machine catalog to package bakery, meat, produce, and more.

You reduce human contact with automated systems. You use machines that seal packages tightly and prevent contamination. You meet hygiene standards and follow regulations in the packaging industry to protect your customers.

You increase production speed and reduce errors. You save on labor costs and improve consistency. You use automated machines to extend shelf life and enhance product appearance.

You use labeling machines that print expiration dates, batch numbers, and allergen information. You check labels for accuracy. You select equipment that supports traceability and meets industry standards.

You request machines with adjustable settings and tool-free changeovers. You choose models that handle different sizes and shapes. You explore customization options in the Stabake Food Packing Machine catalog.